- Products

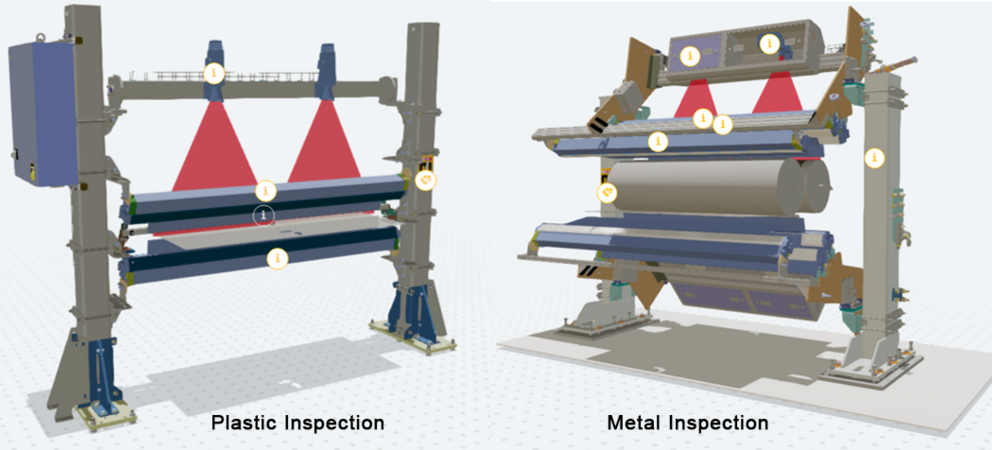

- Plastic Inspection

Ultra-fast, precise & reliable optical plastic inspection and measuring solutions for all kinds of base and converted plastic materials.

Ultra-fast, precise & reliable optical plastic inspection and measuring solutions for all kinds of base and converted plastic materials.- Battery Inspection

- Blown Film Inspection

- Cast Extruded Film Inspection

- Composite Material Inspection

- Flexible Packaging Film Inspection

- Glass Fabrics and Prepreg Material Inspection

- ITO/TCO Hard-Coated Film Inspection

- Release Liner, Label and Tape Inspection

- Laminated Film Inspection

- PCB Material Inspection

- Polarizing Film Inspection

- Stretched Film Inspection

- Window Film Inspection

- Nonwoven Inspection

Local defect detection for many different nonwoven technologies (spundbond, spunlaced, meltblown, composite, wetlaid, airlaid, carded, needlepunched, thermal bond) and continuous 100% surface monitoring of key properties, e.g. homogeneity, for a low variation coefficient of the production.

Local defect detection for many different nonwoven technologies (spundbond, spunlaced, meltblown, composite, wetlaid, airlaid, carded, needlepunched, thermal bond) and continuous 100% surface monitoring of key properties, e.g. homogeneity, for a low variation coefficient of the production. - Metal Inspection

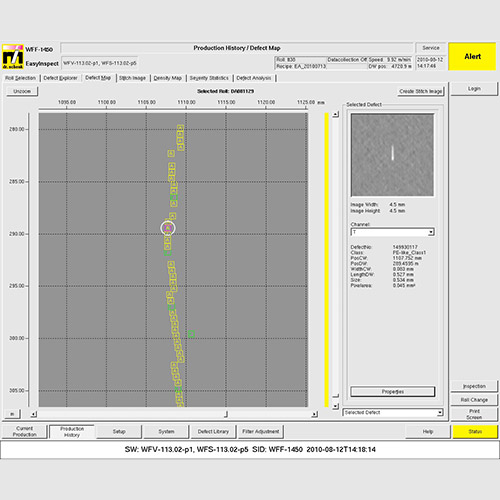

Fast, reliable, and efficient optimization of production and product quality for metals with EasyInspect & EasyMeasure.

Fast, reliable, and efficient optimization of production and product quality for metals with EasyInspect & EasyMeasure. - Paper Inspection

Reliable defect detection, monitoring of presence, position and properties of security features and geometry measurement of paper sheets.

Reliable defect detection, monitoring of presence, position and properties of security features and geometry measurement of paper sheets. - Glass Inspection

Defect detection and large area property monitoring solutions for all kinds of flat glass.

Defect detection and large area property monitoring solutions for all kinds of flat glass. - Display and Touch Panel Inspection

Display and touch panel inspection for reliable inline quality control of all kinds of manufacturing technologies.

Display and touch panel inspection for reliable inline quality control of all kinds of manufacturing technologies. - New Energy Solutions

Inspection solutions for nearly every step in the production of lithium-ion batteries, fuel cells and solar cells.

Inspection solutions for nearly every step in the production of lithium-ion batteries, fuel cells and solar cells. - Structured Surfaces

Complete optical inspection solutions for structured materials: detection of natural marks on cow hides and wood as well as defect detection on the surfaces of synthetic leather, in carbon fibres, textiles and fabrics.

Complete optical inspection solutions for structured materials: detection of natural marks on cow hides and wood as well as defect detection on the surfaces of synthetic leather, in carbon fibres, textiles and fabrics. - Other Applications

The modularity and flexibility of GlassInspect and EasyInspect is also applicable to other market segments and applications in specialty markets.

The modularity and flexibility of GlassInspect and EasyInspect is also applicable to other market segments and applications in specialty markets. - AI Solutions

AI solutions by Dr. Schenk: artificial intelligence, deep learning and neuronal network architecture assist you in your daily work

AI solutions by Dr. Schenk: artificial intelligence, deep learning and neuronal network architecture assist you in your daily work - Consulting Services

Dr. Schenk customers benefit from more than 35 years of experience. You, too, can rely on us when you implement a new system or switch from another system to an automatic in-line inspection solution from Dr. Schenk.

Dr. Schenk customers benefit from more than 35 years of experience. You, too, can rely on us when you implement a new system or switch from another system to an automatic in-line inspection solution from Dr. Schenk. - Customized Solutions

Dr. Schenk offers extensive from-lab-to-fab knowledge for customized solutions. Customers benefit from our expertise in the translation of lab applications to large scale productions.

Dr. Schenk offers extensive from-lab-to-fab knowledge for customized solutions. Customers benefit from our expertise in the translation of lab applications to large scale productions. - Material Handling Solutions

Integrated handling and inspection solutions for customers who want material handling & inspection from a single source - without loss of time or money for coordinating different providers.

Integrated handling and inspection solutions for customers who want material handling & inspection from a single source - without loss of time or money for coordinating different providers.

- Plastic Inspection

- Company

- Publications

- References

- Support & Training

- Career

- Events

International

International Deutsch

Deutsch US

US 中文

中文 日本語

日本語